Industrial Supplies

APT is a Florida distributor of industrial supplies for over 200 companies who serve the metalworking industry. We carry a wide variety of manufacturing solutions including the following:

- Machine tool accessories

- Cutting tools

- Abrasives

- Cutting fluids & lubricants

- Work & tool holding

- And more

Industrial Supply Solutions for Your Shop

We pride ourselves on providing the latest and most superior products to meet the demanding challenges and constant changes in today’s metalworking industry landscape. Our on-staff machining specialists are strongly committed to customer service, timely delivery and technical expertise. Our strong customer relationships, combined with fresh ideas, have been the key to our sustained success. Unsure if we carry the industrial supply solutions you’re looking for? Contact us for your industrial supply needs!

See our full linecard

CATEGORIES

Abrasives

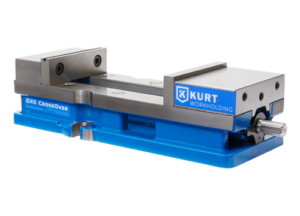

Clamping & Workholding

Fixturing & Workholding

Hand Tools

Holemaking

ALLIED MACHINE

E-Z BURR

EMUGE

EVEREDE

FULLERTON TOOL

IMCO

KYOCERA

MELIN TOOL

OSG

PARLEC

TECHNIKS

WALTER

ARNO ROUSE

BIG DAISHOWA

DAPRA

DENITOOL

DIJET

DORMER PRAMET

DRILLCO

DUMBARTON

EXPRESS CUTTING TOOLS

F+D TOOL

GENSWISS

HANNIBAL

HTC TOOL

KORLOY

MAGAFOR

MASTERCUT

MICRO 100

MIKRON

MITGI

NORTH AMERICAN CARBIDE

PH HORN

PILOT PRECISION

REIFF & NESTOR

TAPMATIC

TITAN USA

TOOLMEX

WEDEVAG

HVAC

Indexable Cutting Tools

Lubricants, Coolants & Fluids

Measuring & Inspecting

Milling

CARMEX

DORIAN TOOL

EMUGE

EVEREDE

FULLERTON TOOL

IMCO

KYOCERA

MELIN TOOL

OSG

TOOL-FLO

WALTER

ABS IMPORT (ALL)

AB TOOLS (SOLID)

BENZ

BIG DAISHOWA

CNC INDEXING

CRYSTALLUME

DAPRA

DENITOOL

DESTINY TOOL

DIJET

DORMER PRAMET

DUMBARTON

EXPRESS CUTTING TOOLS

GEN SWISS

HANNIBAL

HTC TOOL

DESTINY TOOL

KOMA

KORLOY

MADAULA

MAGAFOR

MASTERCUT

MICRO 100

MIKRON

MIL-TEC

MINICUT

MITGI

MYLES

NORTH AMERICAN CARBIDE

PH HORN

PILOT PREC

ROYAL PRODUCTS

PROMAX

REGAL

SCIENTIFIC

SEV CAL

TITAN USA

TOOLMEX

WHITESIDE

WINDIN

Power Tools

ATLAS COPCO

FEIN

KALAMAZOO IND

NILFISK

NSK

PROTO

SUHNER

WHM TOOLGROUP

Saw Blades

FULLERTON TOOL

AB TOOLS

ARNTZ

BITNER

CONTINENTAL DIAMOND

DIAMOND SAWS

F+D TOOL

GAYLEE

GEN SWISS

HANNIBAL

KORLOY

MARTINDALE

MIL-TEC

PH HORN

ROENTGEN

STERLING

TOOLMEX

TOWER LEAF

Threading

Toolholding & Tooling systems

Turning & Boring

CARMEX

DORIAN TOOL

EVEREDE

FULLERTON TOOL

KYOCERA

PARLEC

TOOL-FLO

WALTER

ABS IMPORT

AB TOOLS

ALORIS TOOL

ARNO ROUSE

A+S WORKHOLDING

BIG DAISHOWA

BUCK CHUCK

CRYSTALLUME

DENITOOL

DILLON MANUFACTURING

DORMER PRAMET

EXPRESS CUTTING TOOLS

E-Z BURR

GENSWISS

GLOBAL CNC

HANNIBAL

SOUTHWEST + MEISTER

KEB

KITAGAWA

KORLOY

MICRO 100

NORTH AMERICAN CARBIDE

PH HORN

PILOT PREC.

PRATTS BURNERD

RITEN

ROYAL PRODUCTS

RSVP

SAMCHULLY

SCIENTIFIC

SMW

SUPERIOR CINCINNATI

TOOLMEX

WHIZCUT